North Star Craft Brewery

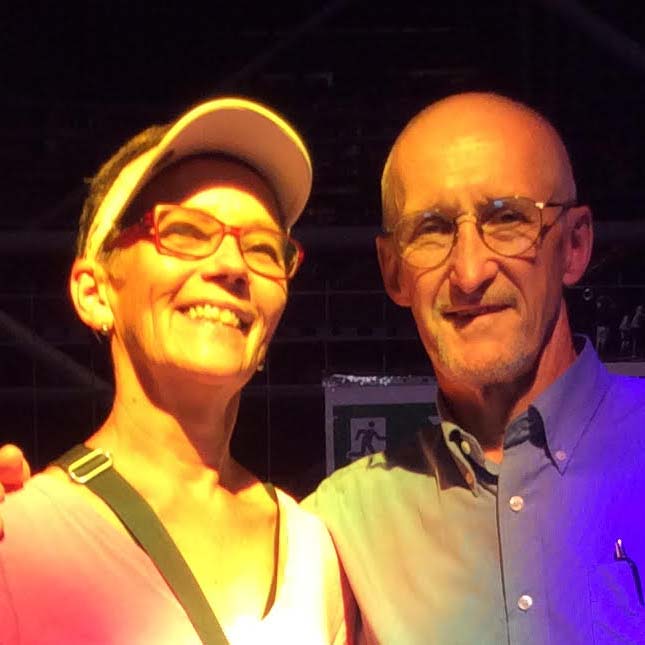

Story by Earl Bloor and Candace Byrne; photos by Earl Bloor

From the bar at North Star Craft Brewery, Shawn Sease, the brewery’s owner and brewmaster, notices the car circling the parking lot at about 4 pm. He quickly crosses the room and flips the sign in the window to signify that the pub is now open. After parking, Susan and David enter the pub, take seats at the bar and, without hesitating, order pints of IPA. An avid motorcyclist from Scott Valley, nestled in the rugged mountains of northern California near the Etna Brewing Company, David regularly travels to motorcycling events and matches them with nearby microbreweries located via internet searches. This is how David and Susan came to be drinking IPA with us in Shasta Lake that Friday afternoon. Soon after their arrival, the pub regulars, or FOBs—friends of the brewery, explained Shawn—began steadily streaming in. They come for the microbrews, they come for the camaraderie of other FOBs, and they come to connect with the brewmaster.

This brewmaster seems constantly on the move, whether delivering the brew round Redding or working right in North Star Brewery, his hands gesticulating as he speaks. Shawn Sease moved to Redding eleven years ago to set up a software company for document storage. “I grew up writing software as a kid—a gift or something, it made sense to me. I liked the math and the logic.” Before coming to Redding, he worked in the Bay area, where, after long days, he would sometimes stop at microbreweries on the way home. Eventually microbrewery visits were planned into his vacations. And somewhere along the line, brewing became his vocation.

Shawn had already been brewing at home with equipment he received for his twenty-first birthday, so he didn’t come to commercial brewing without experience. He likes the science, which he connects with his computer engineering skills, and he likes the people part: “I still use that side of my brain with the chemistry and quality control in brewing. And I get to use the other side serving people in the pub,” he says. After deciding with business partner Robert Kehoe to build the microbrewery, Shawn completed the intensive American Brewers Guild twenty-two weeks-long Brewing Science and Engineering program and committed to being a full-time beer-maker.

At North Star, Shawn and his apprentice Heath keep three beers brewing at a time. They gently mill malted barley (mostly) and wheat (some), 1000-1300 pounds at a time, and send the milled grain through a hopper into a 20 barrel mash tun, where it is infused with hot water. Malting the grain frees enzymes such as α- and β-amylase. The malted grain is then dried in a kiln and sometimes roasted to a chocolate brown color. Water temperature controls the “mouth-feel” of the beer, and Shawn enjoys playing with the chemistry at this stage. At 148 degrees, β-amylase converts the starch in the malt to lower order sugars such as maltose and glucose and the fermentation yields a dry American lager. At 158 degrees, β-amylase is deactivated, leaving α-amylase to produce large, unfermentable sugars, including dextrins (suspected as the cause of beer-farts from its breakdown in the intestines), and the resulting solution—the wort—yields a sweeter, fuller-bodied beer, like Scotch ale.

At North Star, Shawn and his apprentice Heath keep three beers brewing at a time. They gently mill malted barley (mostly) and wheat (some), 1000-1300 pounds at a time, and send the milled grain through a hopper into a 20 barrel mash tun, where it is infused with hot water. Malting the grain frees enzymes such as α- and β-amylase. The malted grain is then dried in a kiln and sometimes roasted to a chocolate brown color. Water temperature controls the “mouth-feel” of the beer, and Shawn enjoys playing with the chemistry at this stage. At 148 degrees, β-amylase converts the starch in the malt to lower order sugars such as maltose and glucose and the fermentation yields a dry American lager. At 158 degrees, β-amylase is deactivated, leaving α-amylase to produce large, unfermentable sugars, including dextrins (suspected as the cause of beer-farts from its breakdown in the intestines), and the resulting solution—the wort—yields a sweeter, fuller-bodied beer, like Scotch ale.

Along with temperature, time of mashing also controls taste. After sixty to ninety minutes in the mash tun (depending on the beer being prepared), the wort is transferred to the fermentation tank, where it is boiled with added hops for ninety minutes. Returned to eighty degrees, yeast is added, and these little guys—“Yeast, that Fabulous Fungus,” reads a poster on the wall—produce alcohol as a by-product of digesting the simple carbohydrates generated in the mashing. After two weeks, the beer is ready for packaging.

This is what microbreweries are all about: playing with types of grain, playing with the chemistry in the process, tasting the results, and offering tastes to FOBs. Microbreweries sprang up after prohibition. The Volhard Act of 1920 had signaled the beginning of prohibition and closed many large breweries, which couldn’t weather the twelve years it was in force. When the Act was amended in 1932 to allow for 3.2 percent beer, the brewing industry started on its long, slow road to recovery. By the 1980s, beer consumption had returned to the levels achieved before prohibition, and, by the end of the 1990s, hundreds of new breweries were operating in the US. Most of the start-up breweries were very small and thus earned the name microbreweries.

The emerging microbreweries emphasized freshness and experimented with much stronger malt and hop flavors. Shawn doesn’t reveal his recipes, and although Stephen Buhner’s Sacred and Herbal Healing Beers: The Secrets of Ancient Fermentation lies on the counter, he says nothing about actually trying the recipes in the book. About the various recipes he does use, generally the decision is that the most recent recipe always results in the best beer.

Today FOBs use online magazines such as Celebrator to get the latest microbrewery news and study maps posted at The Northwest Brewing News (brewingnews.com/webpdfs/ NWBN/NWBN_California.pdf) to seek out brew pubs as destinations for vacations or weekend road trips. One hundred and six craft or microbreweries and brew pubs were listed in northern California in early March. According to longtime FOB Steve Houk, who may have visited some large percent of these, “It was a great part of our vacations. We got to sample interesting beers, buy pub hats and T-shirts, and sometimes even tour the brewery.”

At the North Star Craft Brewery, Shawn and Robert have built a loyal following of both local and traveling FOBs. Patrons choose from as many as seven different beers at the brewery and select their favorites in local restaurants, bars, markets and liquor stores. In supporting the brewery, they also support other local businesses. Committed to growing the local economy, North Star Craft Brewery purchases goods and services from local vendors whenever possible. Although some products can be purchased at a greater discount at some of the big box stores or bid out on the Internet, North Star understands that keeping money in the community benefits all.

They are working with farmers in the Happy Valley and Bella Vista area to produce hops for the brewery.

And Shawn uses Premiere Brand Meats sausages, hamburgers, deli meats, steaks, and tri-tips for all brewery events and special meals with tastings. Premiere Brand Meats is really local, literally next door to the brewery. The relationship runs two ways: on meat deliveries to the Bay Area, Premiere Brand Meats’ emptied truck stops in Oakland to pick up malt and hops for delivery to North Star.

Candace agrees with Susan and David, IPA (6.2% alcohol, golden hue, floral perfume/pungent aroma dripping with hops) is her favorite. Earl’s is Horizons, a 5.5% alcohol American amber ale, a complex blend of American base malts and just enough British chocolate malt to result in a rich amber ale with a slight bitterness to balance the strong caramel malt back bone.

North Star Craft Brewery is no longer in business.