Duck and Rice Harvest Time!

Greetings from Bruce and Christopher, duck and rice farmers out here on our organic operation in Princeton, California. We’d like to wish everyone a bountiful harvest this season, as the landscape changes around us once again from fields of green to gold and the trees don their vibrant colors to welcome us into fall. Rice harvest is often exciting and nerve-wracking, each year managing all the moving parts, excitement and challenge now compounded by the army of 600 ducks we look after.

Rice harvest is often exciting and nervewracking, each year managing all the moving parts, excitement and challenge now compounded by the army of 600 ducks we look after.

BRUCE SEES THE DUCKS TO HARVEST

In beautiful, picturesque sunrises, singing to my duckies on the way to the field, I would find myself gazing at the rice and the weeds and the beautiful job the ducks were doing to eliminate weeds. I feel amazement tingle along my skin as the ducks gently coo in the calm warm morning. Wow, what sights I have seen throughout the year, as if all the sunrises and sunsets were sent to us perfect every day! Then 10:00 a.m. comes, and we are in the middle of a terrible fiery hot day and it seems as if the hair is burning off my arms as I work in the late summer days.

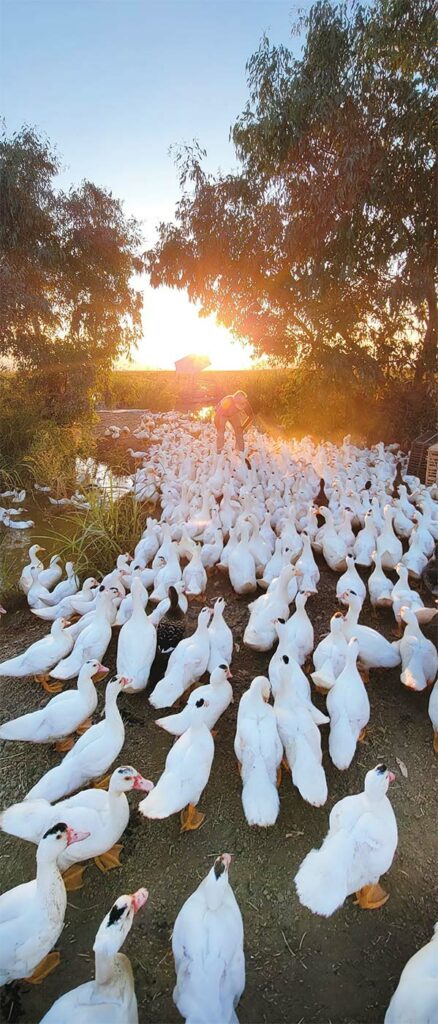

The ducks did not mind swimming in their acre pond for their last few weeks. We had to remove them from the rice fields ninety days before the rice harvest, due to the USDA organic livestock rule. We let the water flow into the duck pond, where the ducks would grow for another four weeks. And grow they did!

Once they’re out of the field, we have to feed them morning, noon, and night! They consume four bags of organic feed a day. I also got some broken organic rice from Chico Rice to feed our ducks; it’s often sifted out in the milling process because consumers prefer whole grains. Soon the time was at hand for the ducks’ second purpose in life: they would be harvested for food. The day our ducks would be processed, we gathered them early in the morning, four to five in a cage. By sun up we had them all loaded and ready for a road trip. It was not a fun trip, as I had grown fond of my ducks. It’s a bittersweet process, but, ultimately, it provides for the community.

Finally, in late October, a forty-foot cargo container carrying our future arrived. It was a historic day for our small farm: after over 100 years of rice farming, we’d finally be able to mill our own rice.

PREPARING FOR THE ONE DUCK REVOLUTION

When we set out to adopt the duck rice farming method, we dreamed of creating a vertically integrated farming operation. The one missing link, in order to bring everything in-house to get our rice to market, was acquiring our own drying and milling equipment. What I did not expect was the incredibly convoluted process of sourcing and shipping equipment from Japan. Fortunately, our mentor in this duck rice farming operation, Erik Andrus, is good friends with a Japanese organic rice importer who believes in duck rice farming and wants to help. Erik helped me source everything we’d need to dry, mill, and package our rice through this importer. Erik is also great friends with Japan’s duck rice master, Mr. Furuno, whom Erik met while living in Japan.

We started our sourcing mission in late June and spent three months monitoring the second-hand market in Japan. That’s when I learned there is a giant market for rice milling equipment, because the average rice farm size is around seven acres. This meant there was a lot of very affordable equipment for sale. We ordered two rice dryers, a huller, a bagging/ sifting unit, and two rice polishers. The huller can mill 1,000 pounds to brown [stage] an hour, and the polishers can each mill fifty pounds to white per hour. The total price shocked me, only around $6,500 for everything.

Shipping was another matter. Due to the shipping crisis in 2022, it would cost $15,000 to ship the equipment. That was a tough pill to swallow. So I took a loan out on my car and used the money to pay for the shipping. Not long after, I received a crash course in international ocean freight shipping. I spent countless hours coordinating sourcing, cleaning, and transporting the machines to the port, and then ensuring the proper loading of the shipping container. Finally, in late October, a forty-foot cargo container carrying our future arrived. It was a historic day for our small farm: after over 100 years of rice farming, we’d finally be able to mill our own rice.

True to the spirit Mr. Furuno put into his PhD dissertation, “The One Duck Revolution,” duck rice farmers are a supportive community and enjoy helping anyone interested in learning the method. Our goal has been to pave the way and lower the barrier to entry for future duck rice farmers. We’re happy to let other farmers use the milling and weeding equipment we acquired–or we can help them source their own equipment on the second-hand market in Japan.

I believe that with more experimentation we can adapt the duck rice method to a much larger scale. One of the difficulties when starting out using this method is getting the ducks to go through the whole field early on. This year we learned the hard way what can happen when they don’t. If the ducks don’t get a chance to work the whole field early in the season, the weeds in the furthest parts can take over.

Fortunately, the rice seedling transplanter we imported from Japan came with an attachment, a six-row weeder. We were stunned at how effective it proved in managing the weeds the ducks didn’t get to in time. Once we saw what it could do, we began to think it possible to convert most of the rice grown in California to organic, using the ducks and the weeder together. With those two tools, we can use less water to grow organic rice regeneratively across the state. It’s been a challenging yet rewarding process adopting the duck rice method. We hope to inspire others to adopt this method.

When I discovered the duck rice method, a light bulb went off in my head: I had found our niche in a very saturated rice market.

SECRET MASTER DUCK RICE PLAN

It was back in 2015 while I was working at Glenn Medical Center that I started thinking about what it would take to build a successful rice business. My coworker Tom Baczkowski was an avid reader and enjoyed business strategy books. He introduced me to a book called The Long Tail, by Chris Anderson, which taught the market strategy of going into the furthest niche of the market and starting to innovate there. The best example he gave was the chocolate industry. For decades Hershey’s dominated the chocolate market. In order to gain market share, new companies formed and created artisanal and ingredient-infused chocolate bars. They had that market to themselves and ate the market from the tail forward.

Growing up, I was fascinated with science, technology and the future. My young mind gravitated towards Elon Musk’s vision of a sustainable electric future. I studied his strategy of how to create a brand and business that differentiates itself in a saturated market. Musk envisioned an innovative production process, a premium product, an engaging story, and a great mission. He started Tesla in the high-end market, where customers who believed in the mission could afford the premium price. These customers got the business off the ground, and that start helped fund the development of more affordable sustainable vehicles.

When I discovered the duck rice method, a light bulb went off in my head: I had found our niche in a very saturated rice market. This method provides a regenerative way of farming rice, saves water, and tells a great story about our adopting it. The method also results in a healthier product for us and the environment because it uses no chemical herbicides or fertilizer. The ducks provide fertilizer, and, when we sell them, we break even on the cost of raising them. Soon, these cost savings along with charging a premium for our rice means we can afford to offer much lower prices to schools as well as donate more rice to those in need.

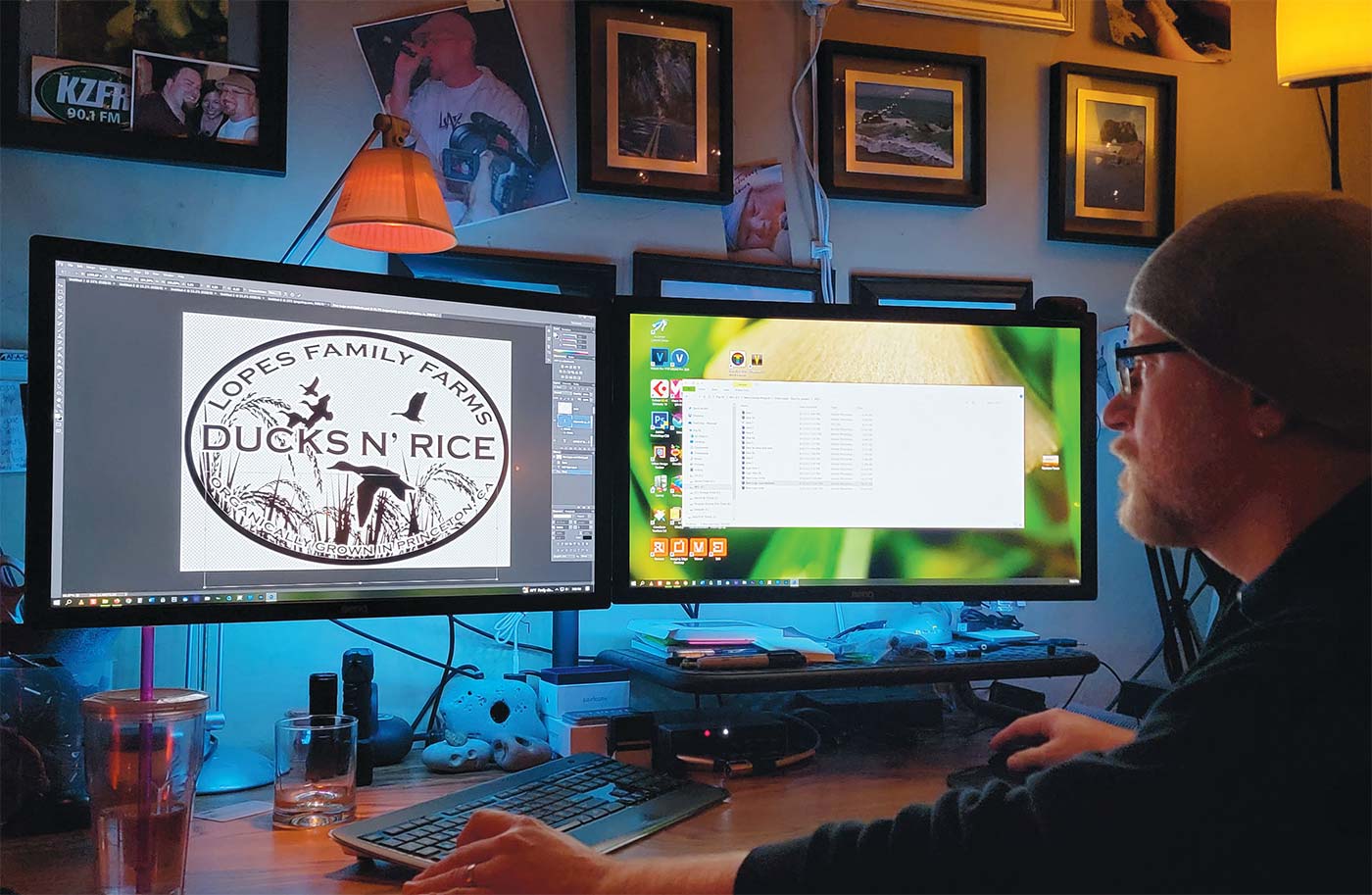

None of our branding would have been a success if it wasn’t for the wisdom and guidance of Chris “Alpine” Woodcox, whom I worked with in CT at Enloe. Alpine is multi-talented in singing, music production, photography, videography, photo and video editing, graphic design, and web design! He and his wife, Katrina, helped us avoid a very early pitfall by suggesting we come up with a better company name than we originally had in mind. He educated us on creating the business and enjoyed spending hours collaborating with us in his studio.

Alpine created the informational flier for our first community pop-up booth, where we had the talented Preston Farris and Erik Petersen serving our duck. Alpine also came up with the design of our logo and rice label. Katrina crafted our story on our website and proofread our writings.

I went to good old faithful, my dad Charlie’s bankout wagon that he had built in 1961 with a military-issued 1945 flathead eight-cylinder Cadillac motor. I put a fresh battery in, poured a little gas down the carburetor, and it fired right up like always.

FARM LIFE IN FALL

Fall requires general maintenance on our harvester and the other equipment for harvest. Yet our daily tasks to grow ducks and rice still engage us. My daily chores start at sunrise, when I release my ducks to the field, clean up after them, and prepare their duck shack for bedtime. After that I’m off checking water, making sure everything’s flowing smoothly. I go to my well, fire up my motor for about an hour while I’m checking the rice, then on the way home turn off the well and proceed to work on my equipment.

We check all the oils, fluids, grease, then we run the harvester for five minutes and check all the bearings with a temperature gun and make sure everything’s in good running order. Then

I do it again for fifteen minutes this time! Then I repeat these steps for each piece of equipment. Because of the drought, we had to pause growing rice for a year. I could have sworn the vehicles were in good running shape when I parked them two years before. I went to start my bankout wagon, which carries rice from field to truck trailer, and I could not get it to start, so I tried my second bankout, picked up from my retired neighbor. As bad luck would sometimes have it, the second would not start either. So I went to good old faithful, my dad Charlie’s bankout wagon that he had built in 1961 with a military-issued 1945 flathead eight-cylinder Cadillac motor. I put a fresh battery in, poured a little gas down the carburetor, and it fired right up like always. Keep your oil changed and they’ll run forever.

With a running bankout, I was feeling really confident that I could whip out forty-one acres of rice. The harvester doesn’t just cut the rice; it also threshes the grain from the stalks and shoots the grain into a tank. To my surprise, the unit that feeds the rice to the threshing part of the machine had worn stripper plates, jamming the rice straw into tangles around the upper shaft. I was stopped in my tracks on my opening round of harvesting! Luckily I was able to get it fixed in a few hours and we were off to the races again.

I made two passes around the field, and my 1992 John Deere harvester was roaring like a lion. I could not believe that she was cutting through my downed rice as if it were still standing and, even better, my grain tank was filling surprisingly fast. Yes, a whopping eighty-nine sack per acre organic crop with hardly any weeds in a year where the average conventional yield was eighty-seven sacks per acre. That’s one for history books.

We were beyond excited to have completed our first successful harvest of ducks ‘n’ rice. We ended up with 30,000 pounds of organic duck rice in twenty-pound bags. Our goal is to sell them to our local school districts in the surrounding four counties with the help of Steve Westaby at Happy Valley Fresh. He does the schools and farmers a great service by sourcing local and delivering products to schools. Now that we have something to give, we are donating bags of rice to local senior nutrition centers, the Jesus Center and are always looking for more places.

It took the combined efforts of our friends, family, and the community to make it through the year to harvest. The ducks inspired us all to come together to make the dream a reality. They are the real heroes of this story, because they tended the rice and then brought joy to people in delicious recipes dreamt up by amazing local chefs. They led the way to a brighter future for our farm, family, community, and environment.

Bruce and Christopher Lopes raise organic ducks and rice on their farm in Princeton, which has been in the family for 113 years. This is the first in a four-part series and introduces readers to the family farm and its latest innovation, ducks ‘n’ rice. The Lopes’ ducks are featured on the menu of Grana and The Winchester Goose in Chico. Once milled this spring, their rice will join the ducks on Grana’s menu.