Third Generation Sharpens the Shop’s Focus

In business for more than a hundred years, Fanno’s Cutlery had its best year in 2020, in the midst of a pandemic. With restaurants closed or shifting to takeout, people were at home cooking more than usual, and they either wanted their kitchen knives sharpened or were on the prowl for new knives. And as gardening became a pandemic pastime too, people also noticed how dull their landscaping tools had become.

People took their blunt blades to Fanno’s.

They also bought more landscaping tools, tools built by Fanno’s. “Saw business was good the last two years. Th e pandemic forced people to stay home, so they did landscaping,” owner Robb Fanno says. “The tree saw was our core business. At some of our dealers, sales were up 300 percent.”

INVENTORS AND BUILDERS

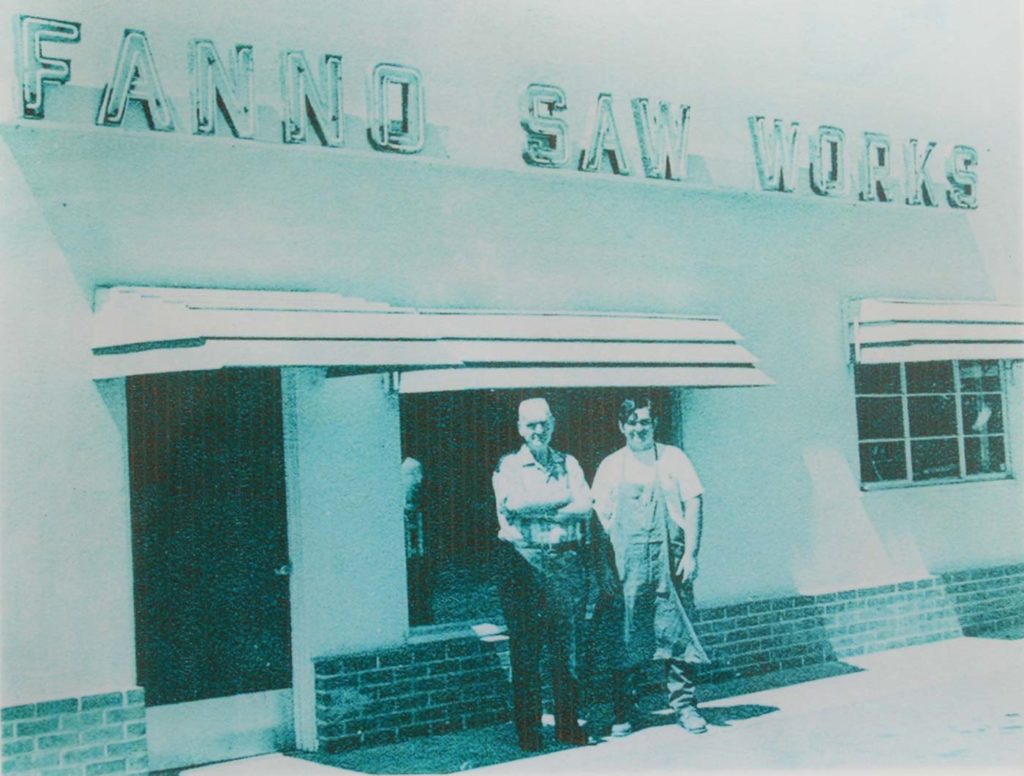

It was Fanno’s grandfather, Asa, who, in 1920, started the Chico company and revolutionized the agricultural saw business, right at the current site on Eighth Avenue in Chico. Asa Fanno had an almond orchard, which, until his invention of the pole saw, required climbing into trees and pruning them with a hand saw. This was dangerous work. The Fanno curved pole saw was the first of its kind. The tooth design and the blade’s curved edge are what made it unique. The apparatus allowed for a safe way to prune those hard-to-reach branches. The operator could do the work standing on the ground—not in the tree or on a ladder.

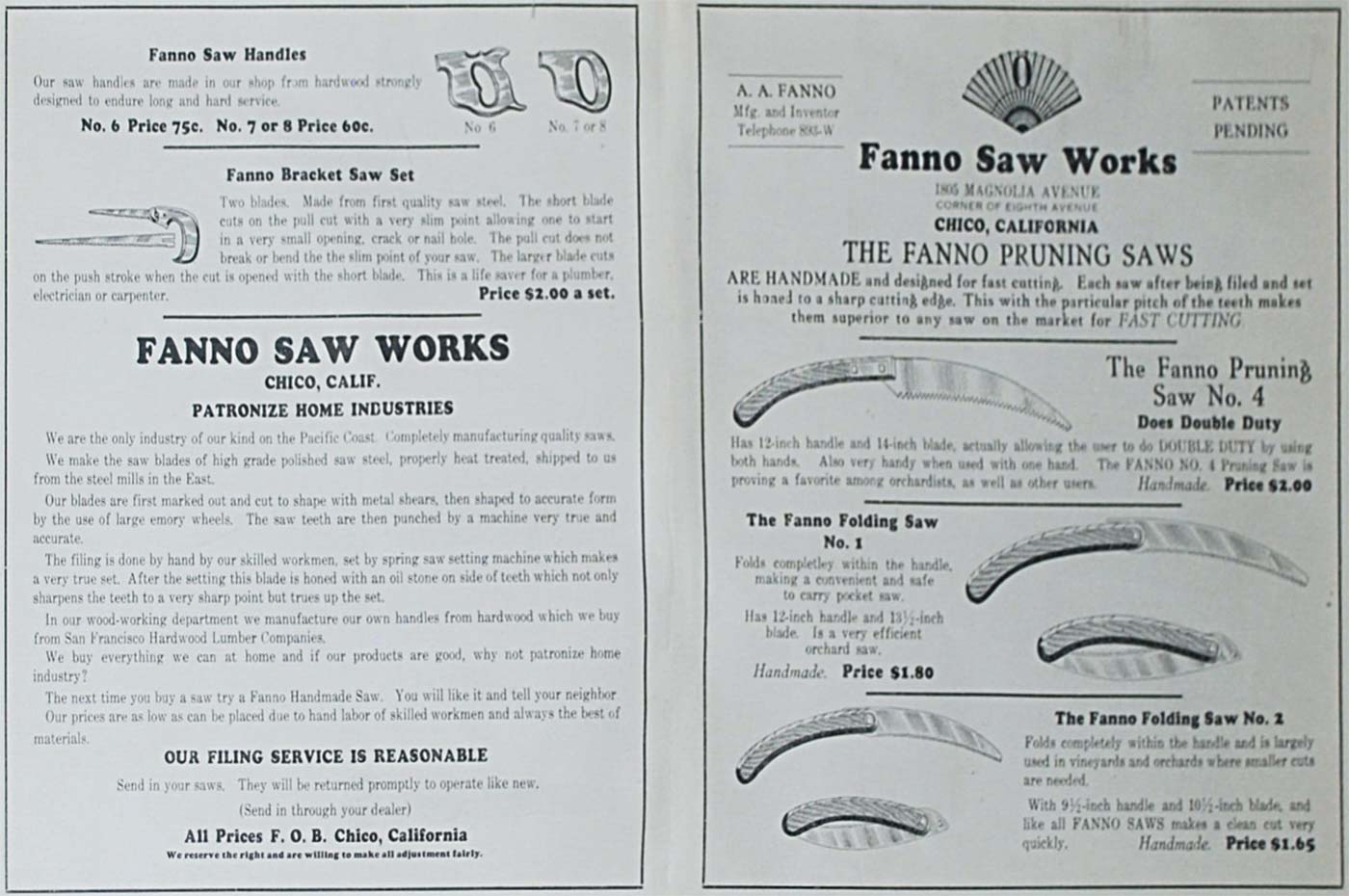

From there, the company developed a folding saw and countless other saws. Those who know a thing or two about these tools know what someone means when they say they own a Fanno—without ever mentioning the word saw.

Being inventors also meant developing the machinery to make the end product. “A lot of the equipment in the 1960s and 1970s we made ourselves because nothing was out there,” Fanno explains. “If it stopped working, we upgraded it ourselves.”

Those who know a thing or two about these tools know what someone means when they say they own a Fanno— without ever mentioning the word saw.

A loyal customer once brought this early catalogue into Fanno’s and jokingly asked if the Company still honored these prices.

MAKING CHANGES

In spring 2021, Fanno sold the saw production business to Superior Fruit Equipment of Washington. That company had been a distributor of Fanno’s saws for more than a quarter century, so the two knew each other well. This was important to Fanno. He wanted to sell to someone whom he trusted to respect the quality of product he and his ancestors had made for a century. Included in the sale was much of the equipment used in the saw making business. “We had a long history of innovation in our tools, but it was based on technology from the 1930s and ‘40s. To be competitive in today’s technological environment is tough,” Fanno admits. “It was the appropriate time to let it go.”

Now the back room is emptier and in some disarray. Fanno is in the process of going through what’s left, acknowledging some of the equipment has outlived its usefulness. “There’s one machine in back that weighs twelve tons and has no value. It was used to blank out the saw blades. It’s equipment that has been outdated,” Fanno points out. It will likely become scrap metal.

KEEPING TOOLS SHARP

Without saws to build, Fanno now focuses on sharpening and sales. The sharpening side of the business came into being on the heels of selling so many saws. Eventually, the saws lost their edge. Saws, loppers, pruning shears— they all need to be sharpened from time to time in order to be effective. Fanno says of the local ag community, “We service the tools they use. They rely on us, and we rely on them.”

For years sharpening tools was more of a side business. But it kept growing even without advertising, and sharpening tools led to sharpening knives. No one else had the experience to sharpen and recondition tools. “It was left up to us to fill that niche,” Fanno says. “We contracted out some of the specialized or heavier stuff .” In the back of the building is a standing abrasive belt grinder where Fanno does his sharpening. Nearby is a bench grinder. Carefully, he runs a knife blade on the belt to get it ready to be used again. A buffer helps finish the process. He tests the short blade in a block of wood; it goes in almost as if wood is butter, proving the knife more than ready to tackle vegetables or meat.

Although some swear by hand-sharpening with a stone, many chefs and home cooks rely on Fanno’s to keep their blades at the ready. Chef Ian Briggs, who owns Butte Creek BBQ with his wife Coco, is a second generation customer. “When I was a kid, my parents owned Sven’s Take-n-Bake Pizza and Subs in Paradise, and my mom would always have their knives sharpened by Mr. Fanno,” Briggs remembers. These days, after he caters events, he takes his knives to be sharpened at Fanno’s. “Prior to taking him my expensive knives, I would buy the lower end knives and use them till they dulled, then just buy new ones,” he explains. “It’s much more cost effective to use a knife that will hold its edge after sharpening. The knives always come back sharp, and turn-around time is pretty quick, couple days is all.”

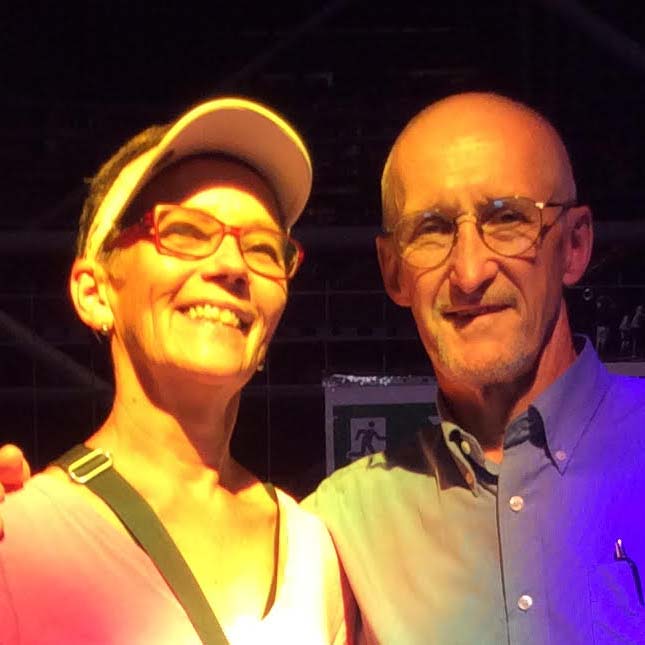

Richard “Chef Richie” Hirshen has been using Robb Fanno’s service for twenty years. This chef has an international resume; locally he has worked at Sierra Nevada Taproom & Restaurant in Chico and Farwood Bar and Grill in Orland. Today he is the corporate chef for Bella Sun Luci. He also teaches gardening and cooking skills to children at Sherwood Montessori School. Says the chef, “I’m happy to be a loyal customer of a local family business. Th ey provide special, personal services.” Hirschen illustrates one such service: “Twelve years ago, Robb ground and rounded the tips of twenty-five serrated paring knives, as a safety measure for my kindergarteners. And I still have, and often use, some of those knives.”

Fanno admits not all the tools people bring in for sharpening should be resurrected. Sometimes sentimentality for a family heirloom or a favorite knife has people override the obvious logic of buying something new. “We try to accommodate people. We take it as a challenge at times,” Fanno says of the mandolin blades, old can openers, and well used hunting knives people bring in. “You have to be somewhat diplomatic with what they have.”

Sharp kitchen knives of all sizes sit in a multitude of cardboard boxes waiting for their owners to pick them up. The teeth on chain saw chains have been sharpened to the point they can split most any wood. They are stored in bags. It’s a system that works for Fanno, even though to the untrained eye it might look chaotic.

Robb Fanno says of the local ag community, “We service the tools they use. They rely on us, and we rely on them.”

EDUCATING HOME LANDSCAPERS

Once a year, for free, Fanno leads a workshop for the Butte County Master Gardeners.

“I think as a gardener it’s important to be educated about tools and tool care,” says Kay Perkins, who runs the education committee for the BCMG. “He is entertaining and helps people make good decisions about tools. He says to look for this kind of steel, this kind of ratchet. He doesn’t try to sell his tools. He tells people what to look for whether it’s his or another brand.” He talks about the kind of edge to look for and explains why. He also talks about design, handles, and all the other parts of a tool.

“I went looking for a certain type of knife and headed toward a more expensive one. [Robb] guided me toward one that was more affordable, and I use it all the time. It’s the perfect size for everything I do in the kitchen.” —customer Laura Lukes

RETAIL SALES

Selling knives and tools not produced by the saw works wasn’t a serious part of the business until the early 1980s. As Fanno tells it, people would ask about products either for themselves or as a gift, and he kept making recommendations. Finally, he realized it would be more profitable to stock items for sale instead of sending people elsewhere.

From the start, Fanno explains, “We wanted to bring in quality stuff . There was too much of the lesser quality merchandise available.” Kitchen tools and some sporting cutlery are the main focus. There was a phase about fifteen years ago when customized collectables were popular. Now, Fanno’s Cutlery carries three quality brands—Victorinox, Miyabi and Wüsthof. “There are a lot of cheap knives out there that I can get, but I want to off er people a product I would use myself,” Fanno says. For sale are individual knives and complete sets. Inventory may change, with the emphasis on quality. “We watch the trends. I’m looking at a couple lines we might move in,” Fanno says, without revealing what those might be.

Robb Fanno’s advice: If someone could only own one kitchen knife, it should be a paring knife or an 8-inch chef ’s knife. The combo would be perfect, especially if it were possible to include a bread knife to make it a trio. Fanno’s Cutlery also sells kitchen shears, as well as loppers and smaller pruning tools for home gardeners. And Fanno sells tools so people can sharpen their own blades. His eyes light up when he walks around the store talking about all the inventory. He’s a wealth of knowledge, explaining why the grip is important or how the shape of the blade will allow for various limbs to be trimmed.

LOOKING FORWARD

Robb Fanno is the third generation to run the Chico store that was started by his grandfather, Asa—better known as A.A. Carl Fanno bought the business in 1949 from his father and ran it until his death in 1976. The youngest Fanno came on board in the early 1970s and has been at the helm ever since. Now, it’s mostly a one-man shop. Fanno parcels out some of the sharpening work to a former employee whose business is Richard Moeller Sharpening Service. Fanno’s wife, Linda, helps out with some of the paperwork.

With no heirs, the 72-year-old will end the Fannos’ time in the business. He’s not quite ready to retire but also doesn’t anticipate working forever. Whether a buyer might come forward remains to be seen, and it would have to be an individual or company whom Fanno would trust taking over what remains of his family’s heritage. After all, it’s not just a business; it’s his name that is on the saws and the signs, a signature of quality. The company’s longevity helped bring in new clientele during the pandemic, while longtime customers continued and renewed their relationship with the shop.

“It’s hard to find someone to offer quality service. It’s one reason we are still here. There is the trust factor. I think people value someone who is in business that long, that we must be doing something right,” Fanno says. “People want that relationship, but we don’t have that as a rule in merchandising and retail.”

Even with Chico growing into a city of more than 100,000 people, Fanno and his shop are evidence that quality service is still relevant. “I remember watching my dad when customers would come in. He was very gregarious,” Fanno says. It’s a trait he exhibits as well, an engaging part of that service. One recent shopper (and master gardener), Chicoan Laura Lukes, discovered Robb’s friendly expertise. “I went looking for a certain type of knife and headed toward a more expensive one. [Robb] guided me toward one that was more affordable,” said Lukes, “and I use it all the time. It’s the perfect size for everything I do in the kitchen.”

Says Fanno, “My vision is to stay here as long as I can with the cutlery and sharpening business.” Those who know hope so. 1

FANNO CUTLERY SHOWROOM

224 W. Eighth Ave., Chico

530.895.1763

fannocutlery.com

Kathryn Reed is the author of guides to hiking around Lake Tahoe in all seasons. Check out her blog at kathrynreed.com.